Planetary Mixer vs. Spiral Mixer: What’s the Difference?

Baking bread on a commercial scale requires serious mixing power. What’s the difference between planetary and spiral mixers, and which is best suited to your bakery? These specialized machines both efficiently knead large batches of dough but achieve it in different ways. Planetary mixers mimic the motion of hand kneading, while spiral mixers rapidly extrude dough pieces for thorough gluten development. Understanding how each unique mixer works will help you decide which heavy-duty appliance can best proof, develop, and aerate your dough. Get ready to find out whether the intensive mixing action of a spiral or the gentle kneading of a planetary will give your loaves the ideal structure. The right choice comes down to your bread style and production workflow.

Key Takeaways

The main difference comes down to the mixing action. Planetary mixers have a single agitator that orbits the bowl in a planet-like motion, kneading dough gently. Spiral mixers use a high-speed dual agitator that intensely kneads by forcing dough outward.

Planetary mixing is best for delicate doughs like enriched bread and croissants, providing controlled development. Spiral mixers work well for hearty or whole-grain doughs with rapidly developing gluten.

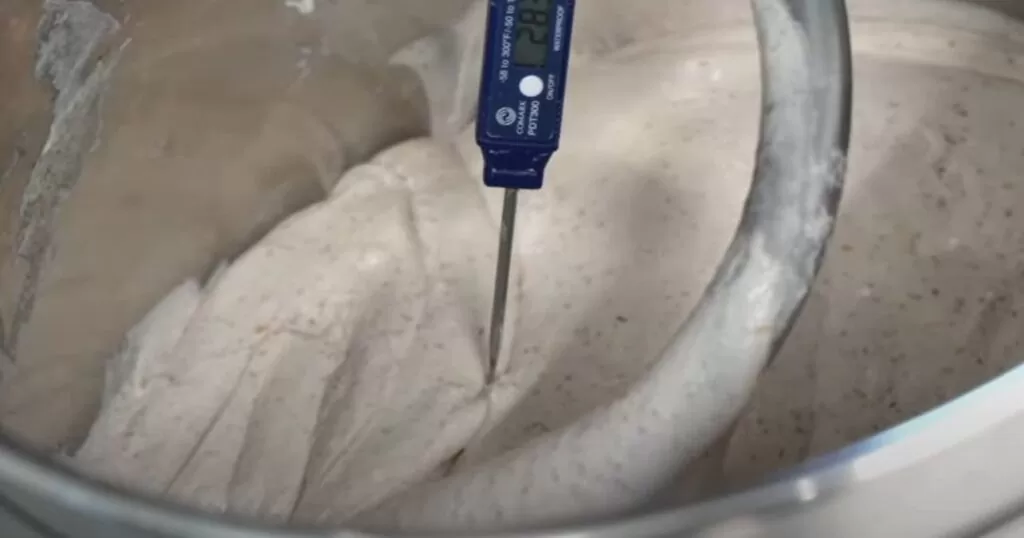

Planetary models operate more quietly at slower speeds, while spiral mixers generate more noise and heat. For artisan breads, planetary mixers allow excellent dough finesse. But spiral mixers efficiently handle large batches for wholesale baking. Evaluate your production, dough, and workflow to choose the right machine for your needs!

Planetary Mixers

What is a Planetary Mixer?

A planetary mixer is a commercial-grade mixer designed specifically for heavy mixing tasks like kneading dough and whipping cream. Planetary mixers are named for the unique way the single mixing implement revolves around the stationary bowl, similar to how planets orbit the sun.

The key components of a planetary mixer include a fixed bowl, a single mixing implement like a spiral dough hook or paddle, a variable speed motor, and a gear transmission system. As the mixing implement rotates on its own axis, it also travels along the inside wall of the bowl in a planetary motion. This provides thorough mixing action without overworking the ingredients.

How Do Planetary Mixers Work?

Here are the key aspects of how planetary mixers mix:

- Fixed bowl – The stainless steel bowl stays stationary and holds ingredients as they are mixed. Common bowl capacities are 20, 30, 40, and 60 quarts.

- Mixing implements – This paddle, whip, or dough hook accessory attaches to the mixer’s drive shaft to mix ingredients in the bowl.

- Planetary movement – The mixing implement rotates on its own axis while also traveling around the bowl wall in a planet-like orbit.

- Variable speed motor lets you adjust mixing speeds, typically ranging from around 20 to 120 RPM.

- Gear transmission – Provides different gear ratios to achieve various mixing speeds. It helps produce torque for dough kneading.

- Digital timer – Allows programming mix times and provides auto shut-off.

As ingredients are mixed, the implement’s planetary movement provides thorough incorporation without overworking them. Friction from the rounded bowl walls also aids the mixing action.

Key Benefits of Planetary Mixers

Planetary mixers provide several advantages for commercial baking:

- Versatility – Can mix, whip, knead, cream, and more with attachment changes.

- Control – Variable speed motor allows controlled mixing intensity.

- Durability – Made of sturdy stainless steel to withstand heavy use.

- Capacity – Bowls sizes from 20 to 60+ quarts accommodate large batches.

- Efficiency – Hands-free operation is faster than manual mixing.

- Consistency – Ensure uniform mixing with each use.

For bakeries producing a range of products, planetary mixers offer excellent flexibility.

Potential Limitations to Consider

Some potential limitations to note include:

- Single bowl – Requires stopping to remove mixed contents before a new batch.

- Bowl capacity – Individual batches over 60 quarts may require a spiral mixer.

- Bulky size – Significant footprint; may not fit smaller kitchens.

- Noise – Mixing action can generate noise, especially at higher speeds.

- Cost – Quality commercial models are a significant investment.

- Learning curve – It takes training and practice to master mixer operation.

Types of Planetary Mixer Models

There are a few key types of planetary mixer models:

Countertop Models

Compact mixers designed for tabletop use. Ideal for smaller kitchens. Bowls around 5-20 quarts.

Pros

- Small footprint

- Maneuverable

Cons

- Low capacities for high-volume production

Floor Models

The standard floor model stand mixers are used in most commercial kitchens. Bowls of 20-40 quarts.

Pros

- Larger capacities

- Powerful mixing output

Cons

- Bulky footprint

Large Bowl Models

Extra powerful floor models are able to handle very large 60-140 quart bowls. Made for mass batch production.

Pros

- Very high volume capacity

- Efficient for large-scale baking

Cons

- Heavy, expensive investment

- Substantial footprint

Key Features to Evaluate

When selecting a planetary mixer, key features to consider include:

- Motor horsepower – Determines available torque for mixing dough loads. 1-3 HP motors common.

- Gearbox – Should have strong, heat-treated hardened steel gears. Helical gearing provides smooth power transmission.

- Bowl material – Stainless steel bowls offer durability; some models offer cold-rolled steel.

- Bowl capacity – Small 20 qt batches up to large 60-140 qt batches accommodated.

- Variable speed – Look for a wide range of 20-120 RPMs.

- Safety features – Lever lock bowls, emergency stop buttons, and auto shut-off are important.

- Attachments – Standard spiral dough hooks, whips, paddles. Accessory ports allow adding attachments.

Useful Planetary Mixer Attachments

- Dough hooks – The spiral dough hooks are essential for kneading bread dough.

- Paddles – Aluminum scraper paddles thoroughly mix thick, dense ingredients.

- Wire whips – Whip egg whites or cream with the stainless steel whips.

- Pasta rollers – Roll and cut pasta dough added through the attachment hub.

- Meat grinders – Grind meats for sausages or burgers with a grinder attachment.

- Vegetable slicers – Quickly slice veggies using a slicing/shredding attachment.

Top Planetary Mixer Brands

Some of the leading professional planetary mixer brands include:

- Hobart – The long-standing market leader renowned for commercial mixer durability.

- KitchenAid – Their Professional HD line offers a more affordable commercial option.

- Globe – Specialized in food manufacturing mixers; quality planetary models.

- Uniworld – Affordable prices with a wide range of mixer sizes and options.

- Dynamic Mixers – Focus on reliability and precision; workhorse mixers.

- Avantco – Cost-friendly line of compact countertop planetary models.

Do thorough comparisons to choose the ideal brand for your bakery’s needs and budget.

Tips for Using a Planetary Mixer

Follow these tips for safe, effective planetary mixing:

- Install the mixer securely on a sturdy, level surface.

- Start mixing dry ingredients at a low speed to prevent splashing.

- Gradually increase speed once ingredients are incorporated.

- Use a timer and avoid overmixing batters to maintain aeration.

- Keep hands and objects out until all movement stops.

- Lock bowls in place before mixing and unlock before removing bowls.

- Clean all parts thoroughly after each use.

With practice using the variable speeds and attachments, you’ll become a planetary mixing expert!

Spiral Mixers

What is a Spiral Mixer?

A spiral mixer is a powerful commercial mixer specifically engineered for the intensive mixing and kneading of large dough batches. Spiral mixers are named for their dual spinning spiral agitators that rapidly knead dough.

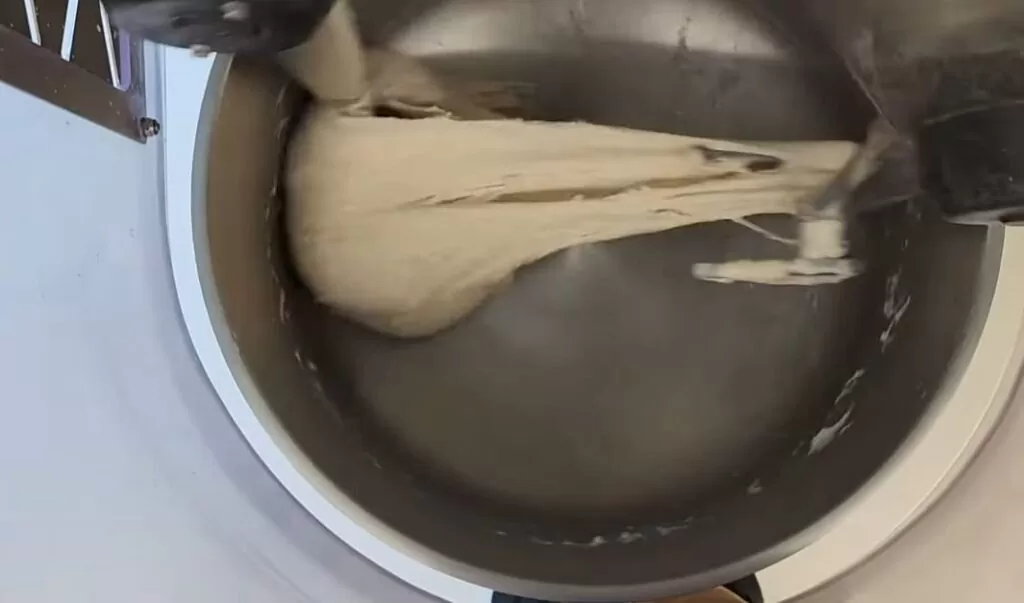

Spiral mixers contain a rotating agitator made of spiral mixing arms inside a fixed or rotating bowl. The high-speed spiral agitator operates at 60-180 RPM to vigorously knead the dough, while some bowl assemblies rotate in the opposite direction. This intense mixing action thoroughly develops dough gluten.

How Do Spiral Mixers Work?

Here are the key mechanisms spiral mixers use to mix and knead dough rapidly:

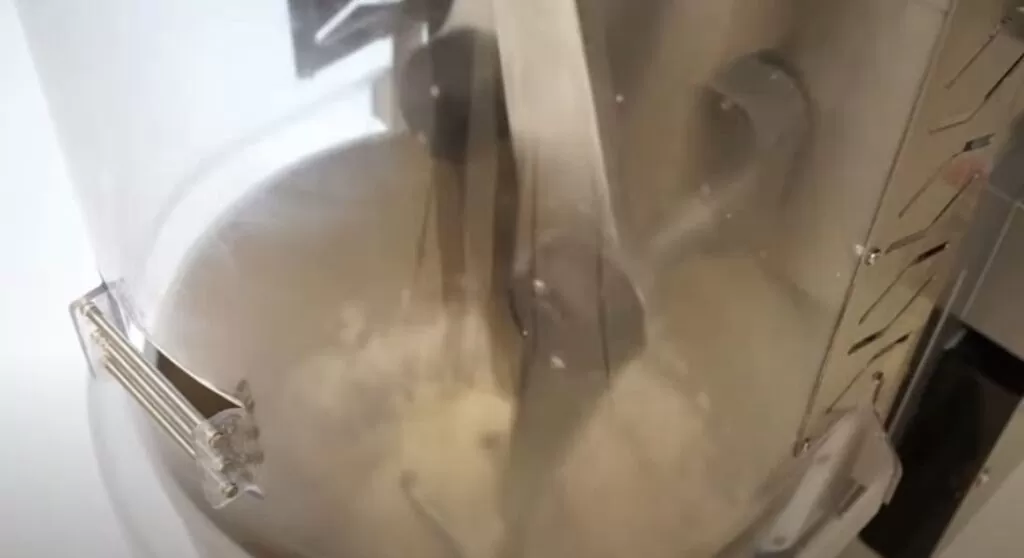

- Dual spiral agitator – Two spiral mixing arms oriented in opposite directions make up the rotating agitator. This creates intense mixing.

- Fixed or rotating bowls – Commercial models have bowls that rotate opposite the agitator. In tabletop models, the bowl remains fixed.

- High RPM – Spiral agitators operate at high speeds, typically between 60 and 180 RPM.

- Extrusion kneading – The high-speed dual arms force dough out towards the bowl walls, stretching and kneading the dough.

- Rapid gluten development – The intensive mixing action develops gluten extremely quickly.

Spiral mixers are ideal for making stiff, high-gluten doughs thanks to the strong extrusion kneading action. This allows efficient mixing of large batches.

Key Benefits of Spiral Mixers

Spiral mixers offer several advantages for high-volume dough:

- Higher capacity – Can efficiently mix very large batches of up to 140+ quarts.

- Rapid mixing – Develops dough strength in as little as 3 minutes.

- Adjustable intensity – Variable speeds allow controlling the rate of gluten development.

- Heavy-duty construction – The rugged design holds up to repeated heavy mixing.

- Power – Strong motors provide plenty of torque for kneading at high speeds.

For industrial bakeries, spiral mixers allow flexible scaling of intensive dough kneading.

Potential Drawbacks to Consider

Some possible downsides of spiral mixers include:

- Noise – The high-RPM motors run louder than planetary models.

- Limited versatility – Primarily designed for dough; not ideal for delicate tasks.

- Complex design – Their dual motors and gears require more maintenance.

- Overmixing risk – Require an experienced user to avoid overworking dough.

- Large footprint – Big tabletop and commercial floor models take up substantial space.

- High cost – Among the priciest commercial mixer options.

Types of Spiral Mixer Models

There are a few main spiral mixer configurations:

Countertop Models

Compact tabletop spiral mixers are ideal for small bakeries. Have fixed bowls and batch sizes around 20-30 quarts.

Pros

- Saves on space

- Maneuverable

Cons

- Limited maximum batch sizes

- Not as heavy-duty

Commercial Floor Models

The standard high-volume spiral mixers. Feature gear-driven rotating bowls and accommodate up to 140-quart batches.

Pros

- Very high capacities

- Ideal for wholesale baking

Cons

- Large footprint

- Higher purchase cost

Industrial Models

Extra powerful, rugged floor models built for round-the-clock production. Feature reinforced motors and gearboxes.

Pros

- Maximum dough batch capacity

- Heavy duty construction

Cons

- Expensive investment

- Very heavy (up to 1500 lb)

Key Features to Evaluate

When selecting a spiral mixer, key features to look for include:

- Motor horsepower – Needs ample power for high-RPM operation even under loads. 5-10+ HP common.

- Variable speed – Digital controls that allow adjusting mixing intensity through a wide RPM range.

- Stainless steel construction – Critical for durability under heavy use and easy cleaning.

- Gearbox – Should have high-quality, hardened steel gears to handle high torque.

- Safety features – Includes enclosed moving parts, emergency stop button, and auto shut-off.

- Warranty – An extended warranty provides peace of mind since it’s a major investment.

- Certifications – Look for NSF commercial sanitation certification.

Useful Spiral Mixer Attachments

- Spiral dough hook – The dual spiral arm agitator is the core mixing attachment.

- Bowl scraper – Scrapes dough off bowl walls during mixing to ensure uniform hydration.

- Dough rounder – For efficiently portioning dough pieces after mixing.

- Vegetable slicer – Attach this slicing/shredding tool to broaden functionality.

- Paddle attachment – Alternative paddle-style agitators for certain doughs.

Top Spiral Mixer Brands

Reputable professional spiral mixer brands include:

- Hobart – The gold standard commercial mixer company that makes legendary mixers.

- Globe – Specialize in food production mixers, including quality spiral models.

- Uniworld – Affordable spiral mixers with great customer support.

- Dynamic Mixer – Reliable mixers built for precision performance and durability.

- Getra – German engineering provides energy efficiency and low noise.

- Power Mix – Basic, affordable mixers are good for smaller bakeries on a budget.

Researching manufacturers thoroughly will help you find the best spiral mixer for your needs.

Tips for Using a Spiral Mixer

Follow these best practices when using a spiral mixer:

- Install the mixer securely on a level, non-slip surface.

- Gradually add ingredients and increase speed to avoid splashing.

- Ensure agitator-to-bowl clearance is properly adjusted.

- Only operate with the bowl properly secured and guards in place.

- Routinely inspect gears and motors for signs of wear.

- Follow manufacturer directions for maintaining and lubricating.

- Unplug and turn off the power before any repairs or cleaning.

With training and experience, spiral mixers can be operated safely and effectively.

Sample Spiral Mixer Dough Recipes

Spiral mixers excel at kneading doughs like:

- Artisan bread loaves

- Bagels

- Pizza doughs

- Pretzels

- Bread rolls and buns

- Croissants

- Whole wheat bread

- Rye bread

- Multigrain bread

- Brioche dough

Explore recipe formulas optimized for the intense kneading of a spiral mixer!

Key Differences Between Planetary and Spiral Mixers

Now that you understand the basics of how each mixer works, here are some of the main differences:

- Mixing action – Planetary mixing is gentler, mimicking hand kneading. Spiral mixing is intense and rapid.

- Mixing speed – Planetary models mix at slower speeds, around 20 to 120 RPMs. Spiral mixers operate at 60 to 180 RPMs.

- Batch size – Planetary models handle 20 to 60-quart batches. Spiral mixers work best for very large batches of up to 140 quarts.

- Gluten development – Spiral mixers develop gluten extremely quickly. Planetary mixers knead more slowly.

- Temperature control – Friction can overheat dough in spiral mixers. Planetary mixers generate less heat.

- Noise level – High-speed spiral mixers run much louder. Planetary mixers operate quietly.

- Maintenance – Spiral mixers require more frequent maintenance with their complex gearing. Planetary mixer upkeep is simpler.

- Cost – Industrial spiral mixers are more expensive than commercial planetary mixers.

FAQ

What kinds of dough is each mixer best suited for?

A gentle planetary mixer is ideal for enriched doughs like brioche that require careful, controlled mixing. Intense spiral mixers use high-protein flour to handle very stiff, high-gluten doughs like bagels and bread.

Which makes better bread dough?

Planetary mixers allow excellent control over the dough structure for artisanal bread, requiring careful gluten development. But a spiral mixer is preferred for consistent, rapid production of hearty breads.

What mixer is better for whole-grain dough?

The strong mixing action of a spiral mixer is advantageous for thoroughly hydrating and developing the structure of dense, heavy whole-grain doughs. A planetary mixer can shear the bran and germ in whole grains.

Which is better for mixing delicate dough?

Low-speed planetary mixing gently kneads doughs like croissants, preserving the delicate layers. The high-impact mixing of a spiral mixer would damage tender dough.

While spiral mixers can mix some cake and cookie batters, a planetary mixer is far better suited for batters requiring a gentle blending action to maintain aeration.

Related Video: Spiral Mixer vs Planetary Mixer Difference | which mixer is Suitable for Bakery Business

Summarize

Understanding the differences between planetary and spiral models is key when investing in a powerful commercial mixer. Planetary mixing provides gentle kneading, ideal for delicate doughs like enriched breads and croissants. Spiral mixers intensely develop gluten through high-speed extrusion action, perfect for hearty bread doughs. Consider batch sizes, dough types, noise, and maintenance needs. Artisanal bakeries often prefer versatile, quiet planetary mixers, while large wholesale bakeries rely on high-output spiral mixers. Weigh your bakery’s needs and workflow to decide between controlled planetary mixing or rapid spiral mixing. With the right pro-grade mixer incorporated into production, you’ll achieve excellent results and quality loaves scaled to your business.

It’s great that you pointed out how planetary mixers would allow excellent control over the dough structure for artisanal bread. I was watching an educational TV show last night and it showed how some mixers were made. From what I’ve seen, it seems there are plenty of mixer types now, one of them is the planetary mixers.