Can You Mix Epoxy Resin With Sand?

Epoxy resin is a versatile material commonly used for a wide range of applications, including coatings, adhesives, and casting. It is known for its excellent durability, resistance to chemicals, and high strength. One question that often arises when working with epoxy resin is whether it can be mixed with other materials, such as sand. Mixing epoxy resin with sand can offer several benefits, such as creating a textured surface, enhancing the material’s strength, and improving its adhesion properties. However, there are also potential drawbacks to consider, such as the impact on the material’s clarity and its curing time. In this article, we will explore the topic of mixing epoxy resin with sand in more detail, including its benefits, drawbacks, and best practices to ensure a successful outcome.

So, Can You Mix Epoxy Resin With Sand?

Yes, it is possible to mix epoxy resin with sand. This mixture can create a textured surface, increase the material’s strength, and improve its adhesion properties. However, the sand used should be clean, dry, and free of any impurities that could affect the resin’s quality and performance. Additionally, the ratio of sand to epoxy resin should be carefully measured to achieve the desired outcome, and the mixture should be thoroughly stirred to ensure even distribution. It’s important to note that mixing epoxy resin with sand can affect the material’s clarity and curing time, so it’s essential to follow the manufacturer’s instructions and best practices to achieve the desired results. Mixing epoxy resin with sand can be a useful technique for various applications, but it’s important to consider the potential benefits and drawbacks before using this method.

Who Created the Epoxy-Sand Mixture?

The technique of mixing epoxy resin with sand is not attributed to any particular individual or company, but rather is a commonly used technique in various industries and applications. The exact origins of this technique are unclear, but it has been used for many years in areas such as construction, art, and DIY projects. Over time, manufacturers have developed specific types of sand and epoxy resin formulations that are designed for use together, and there are now many resources available to guide users on the best practices for mixing and using this material. Ultimately, the use of epoxy resin with sand is a versatile and widely accepted technique that continues to be used and refined by professionals and hobbyists alike.

For What People Begin Mixing Epoxy Resin With Sand?

The practice of mixing epoxy resin with sand has been used by various groups of people for a wide range of applications. Some of the earliest uses were in the construction industry, where the combination of sand and resin was used to create durable and textured flooring surfaces, countertops, and other decorative or functional features. Artists and designers have also used this technique for creating textured paintings, sculptures, and other works of art. Additionally, hobbyists and DIY enthusiasts have used epoxy resin and sand for a variety of personal projects, such as creating jewelry, coasters, and other decorative items. The versatility and durability of epoxy resin and sand make it a popular choice for many people looking to add texture and strength to their creations, and the possibilities for its use are virtually endless.

Composition Of Sand

Sand is a naturally occurring granular material composed of rock fragments, minerals, and other particles. The exact composition of sand can vary depending on the location and the type of rock or mineral that is present in the area. However, most sand is made up of silica or silicon dioxide (SiO2), which is a common mineral found in rocks such as quartz, feldspar, and mica. Other minerals commonly found in sand include calcite, gypsum, magnetite, and hematite. The size and shape of sand particles can also vary, with the most common sizes ranging from 0.063 mm to 2 mm in diameter. The properties of sand, such as its grain size, shape, and mineral composition, can have a significant impact on its performance when mixed with other materials, such as epoxy resin. Therefore, it’s important to consider the type and quality of sand when using it for a particular application.

Composition Of Mixed Epoxy Resin With Sand

The composition of mixed epoxy resin with sand will depend on the specific type and amount of sand used, as well as the ratio of sand to epoxy resin. Generally, when mixing epoxy resin with sand, the sand is added to the resin until the desired consistency and texture is achieved. The ratio of sand to epoxy resin can vary depending on the application, but a common starting point is a 1:1 ratio by volume. This mixture will typically result in a paste-like consistency that can be used for filling gaps, creating textured surfaces, or bonding materials together. The exact composition of the mixture will also depend on the type of epoxy resin used, as well as any additional additives or modifiers that are included in the formulation. Overall, the composition of mixed epoxy resin with sand can be adjusted to achieve a wide range of properties and characteristics, making it a versatile material for various applications.

With What Else I Can Mix Epoxy Resin With Sand

In addition to mixing epoxy resin with sand, there are other materials that can be used to create different textures and properties in the final product. Some of these materials include:

- Gravel or crushed stone: Adding gravel or crushed stone to epoxy resin can create a more durable and textured surface. This mixture is often used in flooring applications or for creating outdoor decorative features.

- Glass beads or microspheres: Mixing epoxy resin with glass beads or microspheres can create a lightweight and insulating material that is often used in aerospace or marine applications.

- Metal or wood shavings: Adding metal or wood shavings to epoxy resin can create a metallic or rustic finish, depending on the type of material used. This mixture is often used for creating decorative items or furniture.

- Pigments or dyes: Adding pigments or dyes to epoxy resin can create a wide range of colors and effects. This mixture is often used in art or jewelry making.

There are many materials that can be mixed with epoxy resin to achieve different textures, properties, and aesthetics. The key is to experiment with different ratios and materials to find the right mixture for the desired application.

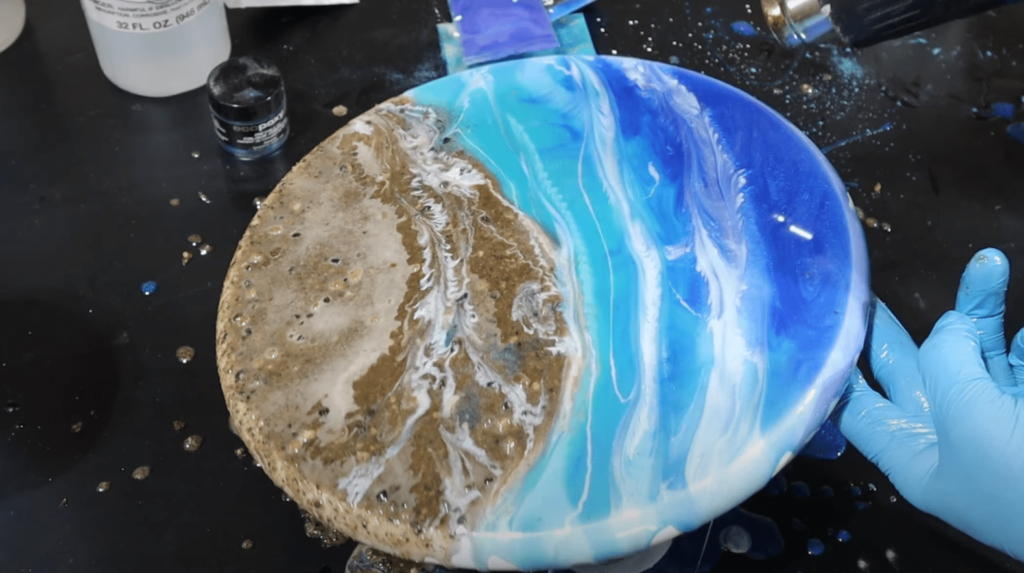

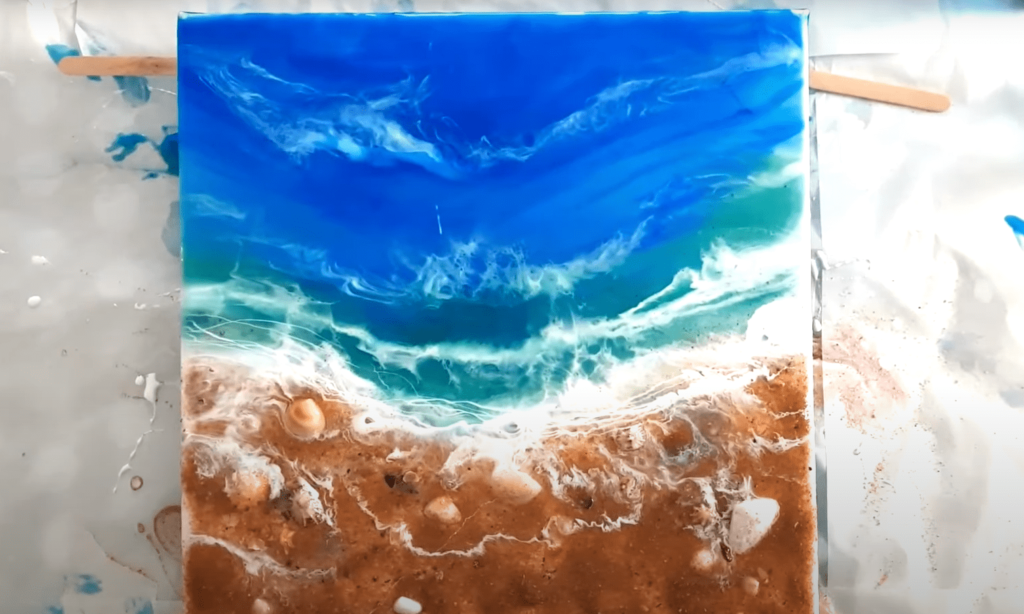

What Can I Create With Mixed Epoxy Resin With Sand?

Mixed epoxy resin with sand can be used for various applications, and the possibilities are virtually endless. Here are some of the things that you can create with mixed epoxy resin with sand:

- Textured surfaces: Mixing epoxy resin with sand can create a textured surface that is often used in flooring, countertops, and other decorative features.

- Bonding materials: Epoxy resin with sand can be used to bond materials together, such as wood, metal, or plastic.

- Filling gaps or cracks: The mixture of epoxy resin with sand can be used to fill gaps or cracks in various materials, such as concrete or wood.

- Sculptures: Artists and sculptors often use epoxy resin with sand to create textured surfaces and add dimension to their works.

- Decorative items: Mixed epoxy resin with sand can be used to create a wide range of decorative items, such as coasters, jewelry, and paperweights.

- DIY projects: Hobbyists and DIY enthusiasts often use mixed epoxy resin with sand for various projects, such as creating custom phone cases, keychains, or even DIY furniture.

Mixed epoxy resin with sand is a versatile material that can be used for a wide range of applications, and the possibilities for creativity and innovation are endless.

Advantages Of Mixing Epoxy Resin With Sand

Mixing epoxy resin with sand offers several advantages over using just epoxy resin or sand alone. Here are some of the advantages of mixing epoxy resin with sand:

- Increased durability: The combination of epoxy resin and sand creates a highly durable material that can withstand wear and tear, making it ideal for high traffic areas or outdoor applications.

- Enhanced texture: Mixing sand with epoxy resin creates a textured surface that can add visual interest and dimension to a variety of projects, such as flooring, countertops, or sculptures.

- Better adhesion: Epoxy resin mixed with sand offers improved adhesion properties, making it an ideal choice for bonding materials together or filling gaps and cracks.

- Improved resistance: The addition of sand to epoxy resin can improve resistance to impact, heat, and chemicals, making it suitable for a wide range of applications.

- Versatility: The combination of epoxy resin and sand can be adjusted to achieve a wide range of properties and characteristics, making it a versatile material for various applications.

Mixing epoxy resin with sand can provide numerous benefits that make it a popular choice for a variety of projects, from industrial to artistic applications.

Disadvantages Of Mixing Epoxy Resin With Sand

While there are many advantages to mixing epoxy resin with sand, there are also some potential disadvantages to consider. Here are some of the disadvantages of mixing epoxy resin with sand:

- Curing time: Mixing epoxy resin with sand can increase the curing time, especially if a large amount of sand is used. This can result in longer wait times before the project can be finished or used.

- Cost: Adding sand to epoxy resin can increase the overall cost of the project, as sand can be relatively expensive, especially if a large amount is needed.

- Difficulty in mixing: Mixing sand with epoxy resin can be a challenging process, especially if a large amount of sand is used. This can result in uneven mixing or clumping, which can affect the final texture and consistency of the mixture.

- Weight: Mixing sand with epoxy resin can increase the weight of the finished product, which may be a concern in some applications.

- Safety: Mixing epoxy resin with sand requires proper safety precautions, such as wearing protective gear, as the epoxy resin and sand mixture can be harmful if it comes into contact with the skin or eyes.

While mixing epoxy resin with sand offers many advantages, it is important to carefully consider the potential disadvantages before starting a project. Proper safety precautions and careful planning can help ensure a successful and safe project.

Which Country Is Created Epoxy Resin?

Epoxy resin was first developed in Germany in the 1930s, specifically by Paul Schlack, a chemist working for the Swiss chemical company Ciba. Since then, the production and use of epoxy resin have expanded globally, with many countries now manufacturing and using this versatile material in various applications. Today, epoxy resin is produced in many countries around the world, including the United States, Japan, China, Germany, and South Korea, among others.

How Epoxy Resin Was Created?

Epoxy resin was created in the 1930s by Paul Schlack, a chemist working for the Swiss chemical company Ciba. Schlack was researching new synthetic materials and came across the compound bisphenol A and epichlorohydrin, which, when combined, formed a clear, hard plastic. He discovered that the resulting substance had a unique ability to bond with various surfaces, making it an excellent adhesive.

Schlack and his team continued to develop and refine the compound, eventually creating the first commercially available epoxy resin in the late 1940s. The use of epoxy resin quickly became popular due to its strength, durability, and versatility. Today, epoxy resin is used in a wide range of applications, including adhesives, coatings, composites, and casting materials, among others.

For What Things I Can Use Epoxy Resin?

Epoxy resin is a versatile material that can be used for a wide range of applications. Here are some common uses of epoxy resin:

- Adhesives: Epoxy resin is a popular choice for industrial and household adhesives due to its strong bonding properties.

- Coatings: Epoxy resin can be used as a protective coating for surfaces such as floors, countertops, and walls, providing a durable and waterproof finish.

- Composites: Epoxy resin is used in the production of composite materials such as fiberglass, carbon fiber, and Kevlar.

- Casting and molding: Epoxy resin can be used to cast and mold a variety of objects, including jewelry, figurines, and other decorative items.

- Marine applications: Epoxy resin is commonly used in marine applications due to its resistance to water and other harsh environmental conditions.

- Electrical and electronic applications: Epoxy resin is used to encapsulate and protect electronic components from moisture, dust, and other contaminants.

- Automotive applications: Epoxy resin is used in automotive applications such as body repair, coatings, and adhesives.

These are just a few examples of the many applications of epoxy resin. Its versatility and durability make it a popular choice for many industries and DIY projects.

What Should You Not Mix Sand For?

Sand is a versatile material that can be mixed with many other materials to create various mixtures. However, there are some materials that should not be mixed with sand due to their potentially hazardous nature. Here are some examples of materials that should not be mixed with sand:

- Chemicals: Sand should not be mixed with chemicals, such as acids, bleach, or ammonia, as this can create a potentially hazardous mixture that can release toxic fumes.

- Heavy metals: Sand should not be mixed with heavy metals, such as lead, mercury, or cadmium, as this can result in a mixture that can be harmful if ingested or inhaled.

- Radioactive materials: Sand should not be mixed with radioactive materials, such as uranium or plutonium, as this can create a mixture that can be potentially hazardous to human health.

- Flammable materials: Sand should not be mixed with flammable materials, such as gasoline, oil, or alcohol, as this can create a potentially explosive mixture.

- Food waste: Sand should not be mixed with food waste or organic matter, as this can create an environment for bacterial growth and produce foul odors.

It is important to always read and follow the manufacturer’s instructions when mixing any materials, including sand, to avoid any potential hazards.

FAQ

How dangerous is it to mix epoxy with sand?

Mixing epoxy resin with sand can be potentially dangerous if proper safety precautions are not taken. Here are some of the potential hazards associated with mixing epoxy resin with sand:

- Skin and eye irritation: Epoxy resin can cause skin and eye irritation if it comes into contact with the skin or eyes. The sand can also cause mechanical irritation to the skin. Proper protective gear, such as gloves and safety goggles, should be worn when mixing and working with epoxy resin and sand.

- Inhalation of fumes: The mixing process of epoxy resin with hardener can release fumes that can be harmful if inhaled. Adequate ventilation should be provided, and a respirator should be worn if necessary.

- Heat generation: The chemical reaction between epoxy resin and hardener generates heat, which can cause the mixture to get hot and potentially cause burns if not handled properly.

- Flammability: Epoxy resin is flammable and can ignite if exposed to high temperatures or an open flame.

- Toxicity: Epoxy resin and hardener can be toxic if ingested. Proper handling and storage are essential to prevent accidental ingestion.

It is important to follow proper safety procedures when mixing epoxy resin with sand to prevent potential hazards. This includes wearing protective gear, ensuring adequate ventilation, and following the manufacturer’s instructions for handling and storing the materials.

Which brands mix epoxy resin with sand?

There are many brands that offer epoxy resin and sand mixture products. Here are a few popular brands:

- West System: West System offers a range of epoxy resin products, including those that can be mixed with sand to create a textured surface.

- MAS Epoxies: MAS Epoxies also offers a range of epoxy resin products that can be mixed with sand to create a textured surface.

- TotalBoat: TotalBoat offers an epoxy-based fairing compound that can be mixed with sand to create a strong, textured surface.

- System Three: System Three offers a range of epoxy resin products, including those that can be mixed with sand to create a textured surface or for use as a structural adhesive.

- Pro Marine Supplies: Pro Marine Supplies offers an epoxy resin kit that includes sand, allowing users to create a textured surface for various projects.

It is important to carefully research and choose the right brand and product for your specific project needs, as each brand may offer different properties and characteristics.

What shouldn’t epoxy and sand be mixed with?

When mixing epoxy resin with sand, there are certain materials that should be avoided. Mixing epoxy resin with incompatible materials can result in a chemical reaction that may cause the mixture to fail or result in unsafe conditions. Here are some materials that should not be mixed with epoxy resin and sand:

- Water: Epoxy resin and water do not mix well together, and adding water to the mixture can cause the epoxy resin to fail to cure properly.

- Acids: Acids can react with the epoxy resin and cause the mixture to fail, resulting in a weak or unstable product.

- Alcohols: Alcohols can react with the epoxy resin and cause it to soften or fail, leading to a weakened or unstable product.

- Strong oxidizing agents: Strong oxidizing agents, such as bleach or hydrogen peroxide, can react with the epoxy resin and cause it to break down, leading to a failed or weakened product.

- Certain plastics: Some types of plastics can be incompatible with epoxy resin and may cause the mixture to fail.

It is important to carefully research and choose compatible materials to mix with epoxy resin and sand to ensure a successful and safe project. Always follow the manufacturer’s instructions and take appropriate safety precautions when working with epoxy resin and sand.

Related Video: Mixing Sand and Salt with Mica in a Resin Casting – Will it Work?

Final Thoughts

Mixing epoxy resin with sand can be a useful technique for creating textured and durable surfaces for a wide range of projects. When mixed correctly, the combination can provide excellent strength, durability, and resistance to water, chemicals, and abrasion. However, it is important to follow proper safety procedures when working with epoxy resin and sand to avoid potential hazards, such as skin and eye irritation, inhalation of fumes, heat generation, flammability, and toxicity. Additionally, it is important to choose compatible materials to mix with epoxy resin to ensure a successful and safe project. By following manufacturer instructions and taking appropriate safety precautions, epoxy resin and sand can be an effective way to create long-lasting and attractive surfaces for a variety of applications.